octoplant

Full control for production plants and industrial automation

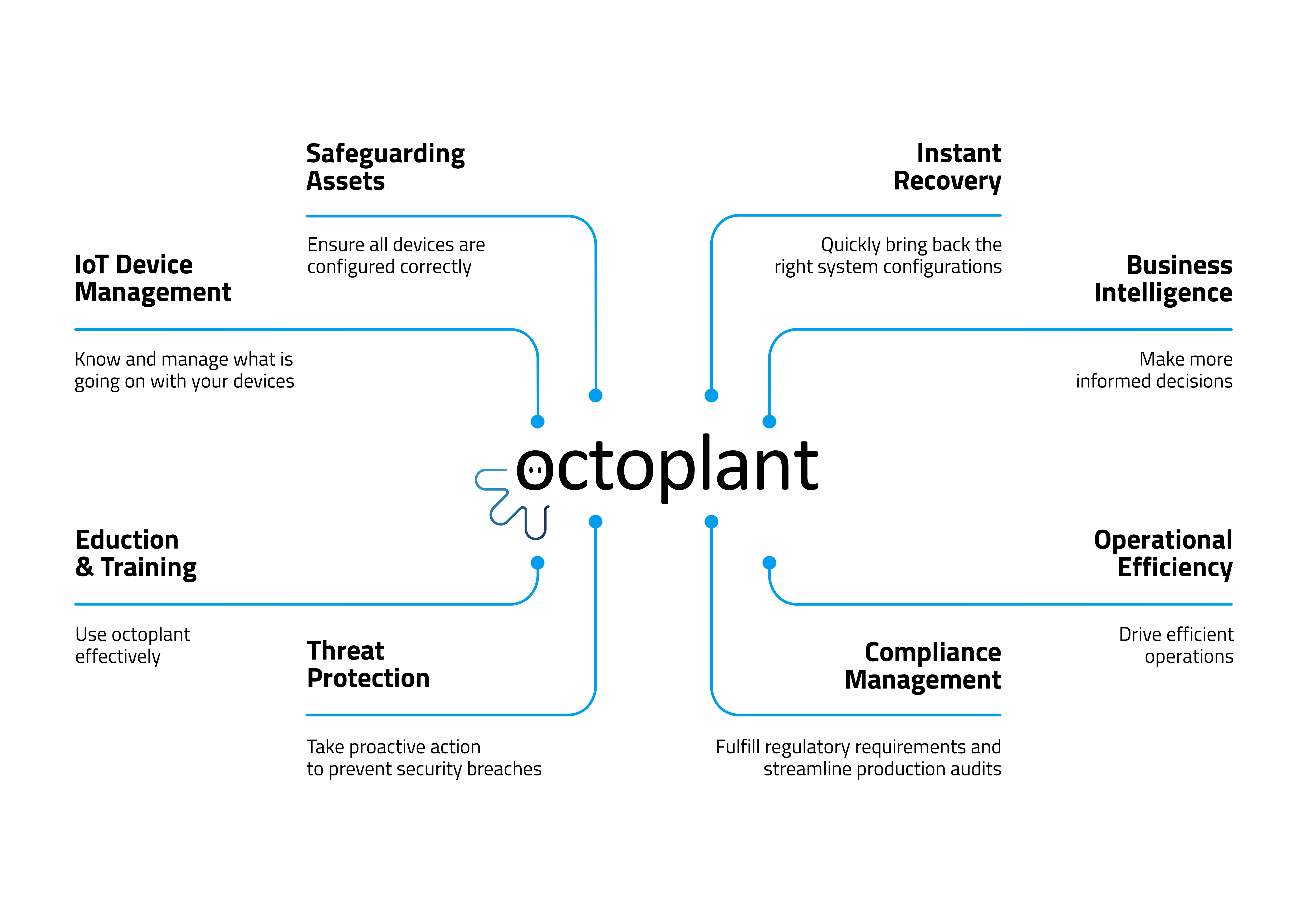

octoplant ensures data consistency and greater protection in production plants. The modular software platform offers comprehensive asset and device management as well as backups, adapted to the individual challenges of your industrial plant. Business intelligence enables consistent data evaluation, unlocking valuable insights.

Centralize data

for complete clarity

Detect cyberattacks

for more security

Increase productivity

and radically reduce downtime

Speed up disaster recovery

with the right control program version

Want to know more?

The octoplant promise: Keep production running!

Industrial plants are becoming increasingly complex. The growing number of IoT devices, sensors, and field devices, as well as more suppliers and service providers, are driving an increase in data points. Adding to the complexity are 24/7 operations with tightening set-up times, smaller batch sizes, and external challenges such as compliance, regulation, and cyber risks.

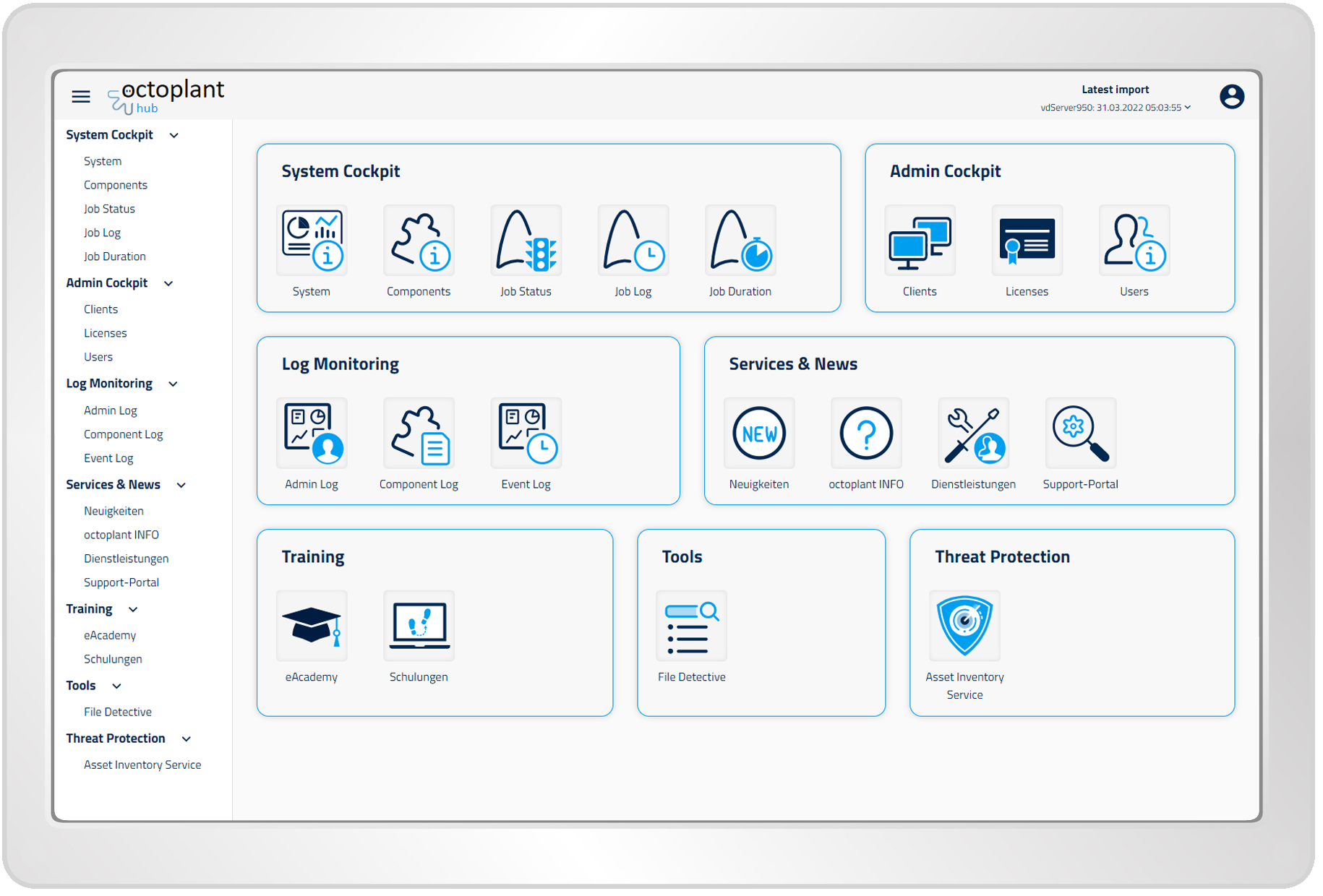

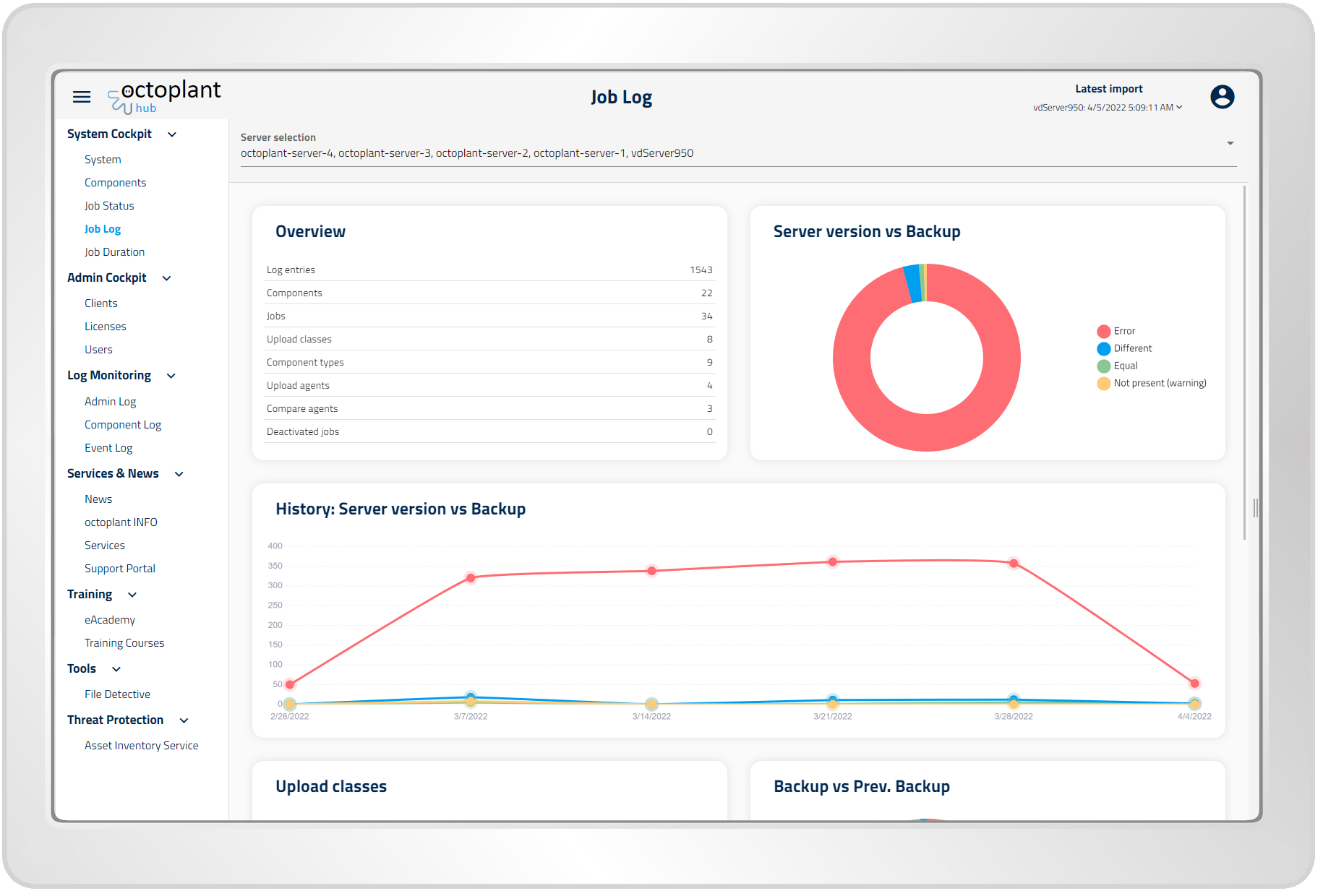

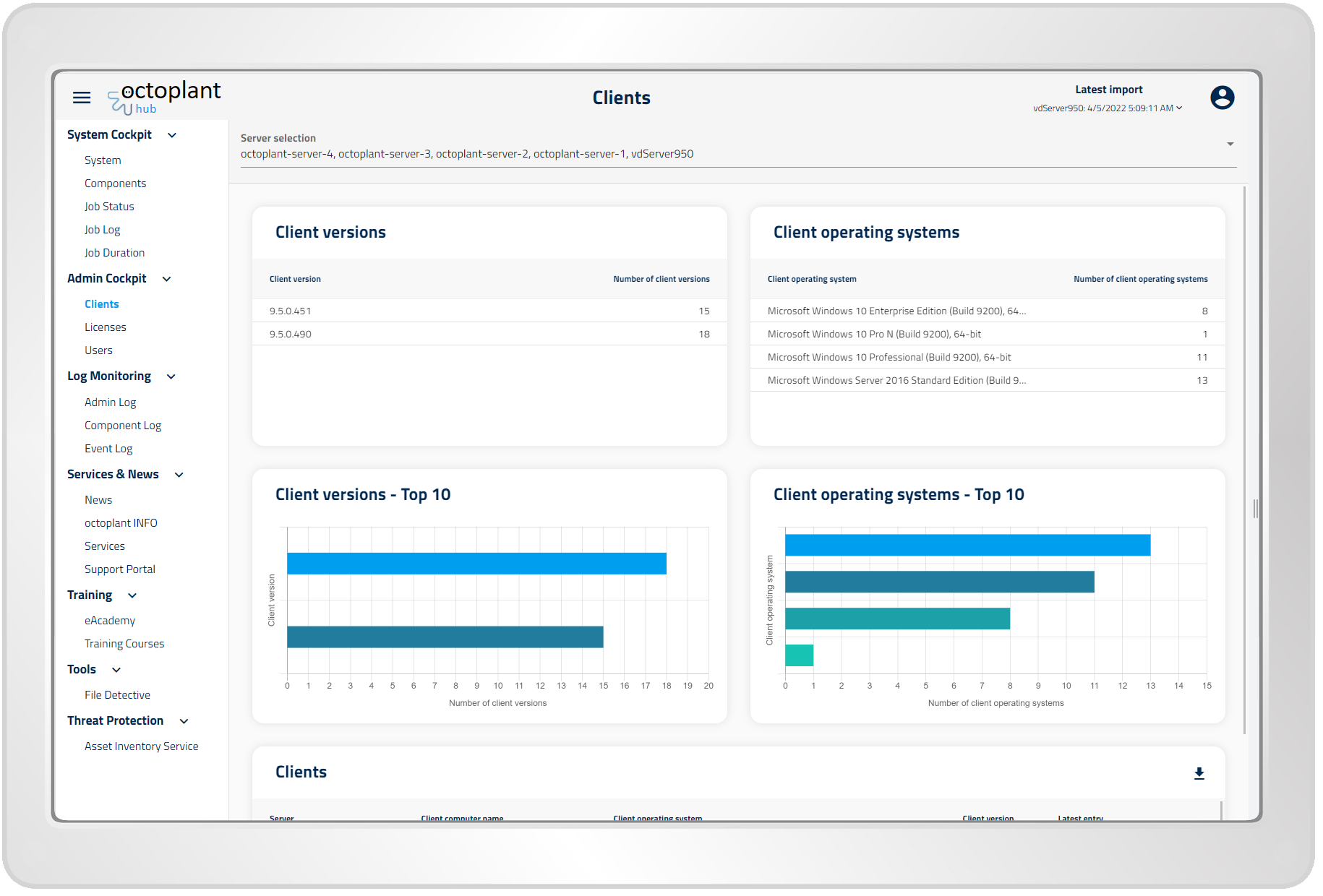

octoplant hub

The octoplant hub uses dashboards to provide information about production, maintenance, and management. You can use it to access, analyze, and monitor data taken from numerous octoplant servers.

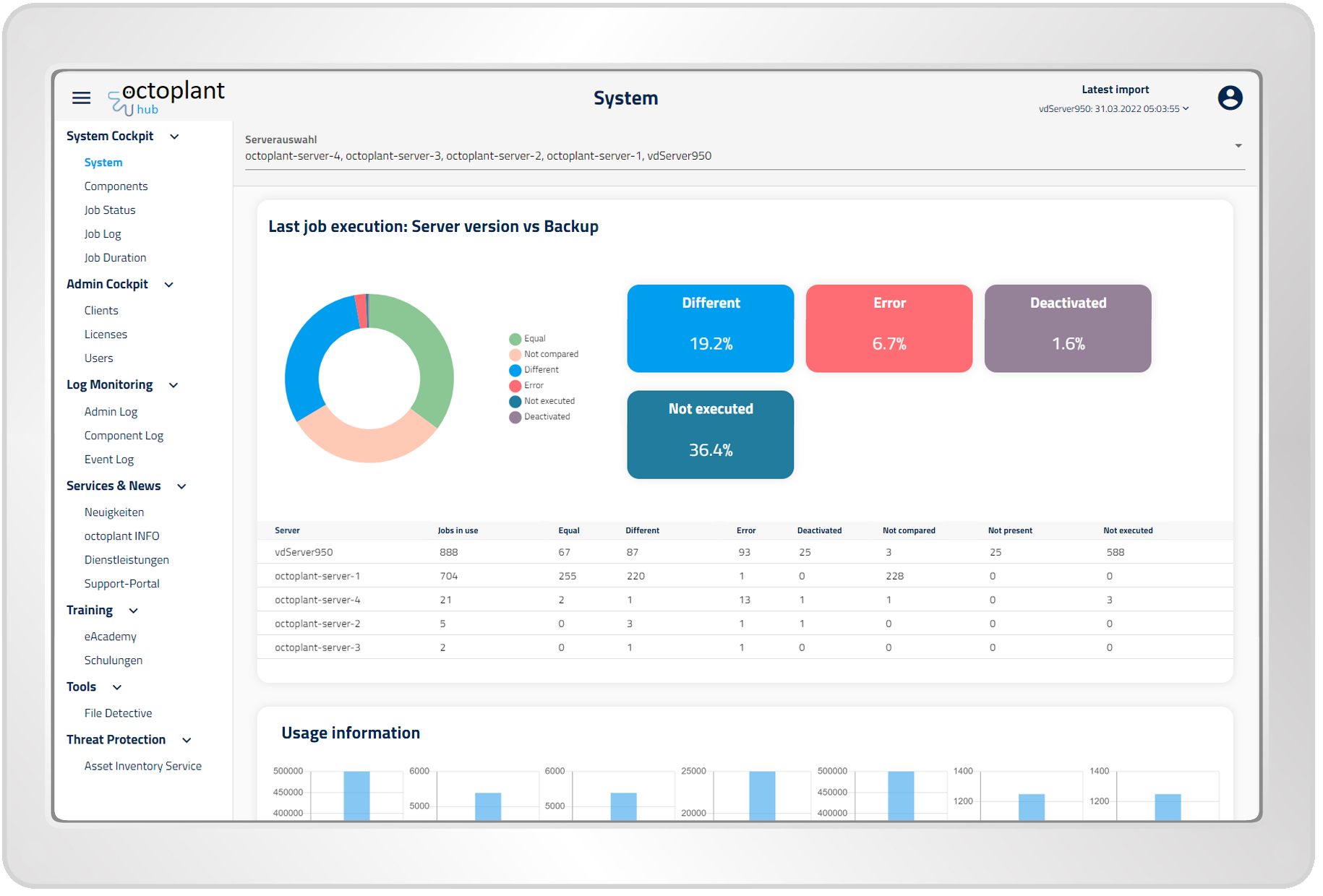

System cockpit

The System Cockpit provides information and transparency about the degree of utilization of octoplant. Questions such as “How many jobs are active, deactivated?” or “Which jobs led to an error?” can be easily answered here.

Job log

Job Log lists the history of all jobs results. It provides a graphical analysis of job results (Equal, Different, Error, etc.) and allows the interactive filtering and sorting needed for analyzing the history of specific jobs.

Admin cockpit

Dashboards and reporting functionalities with overviews of users, clients and licenses are available in the admin cockpit.

Reduce costs

- Cut the duration of downtime or avoid it altogether

- Improve efficiency when commissioning new production lines

- Simplify day-to-day work processes, such as documentation, backup and troubleshooting

- Quickly find and restore a previous correctly-functioning version

Improve processes

- See at a glance WHO changed WHAT WHERE, WHEN and WHY

- Analyze projects, e.g. find points of frequent change

- Access documentation for audit trails and QM processes

- Simplify coordination with external contractors

Increase certainty, safety and security

- Detect unauthorized changes to running control programs

- Ensure full traceablilty and fast disaster recovery

- Easily generate change history reports (for audits etc.)

- Quickly replace corrupted or erroneous programs

Customer satisfaction

96% of our customers would recommend octoplant!

Source: Customer survey 2018-2020

Overcoming complexity with octoplant

- Get an overview of your asset landscape, organize devices and drivers, and log the history of changes

- Create (automatic) backups and stay up to date on (unplanned) changes – with full visibility of any deviations

- Reduce downtime and use the change history to restore configurations. Accurately find the correct version you need

- Get an overview of your automation ecosystem data with an easy-to-use data analytics platform

- Improve overall equipment effectiveness (OEE) through standardization, synchronization, increased visibility, and system integration

- Implement regulatory workflows and compliance requirements and easily provide the necessary documentation for audits

- Identify potential risks or vulnerabilities and receive recommendations for maximum reliability and resilience

Try octoplant extensively for 30 days for free

See for yourself why more than 2,400 customers trust in AUVESTY-MDT

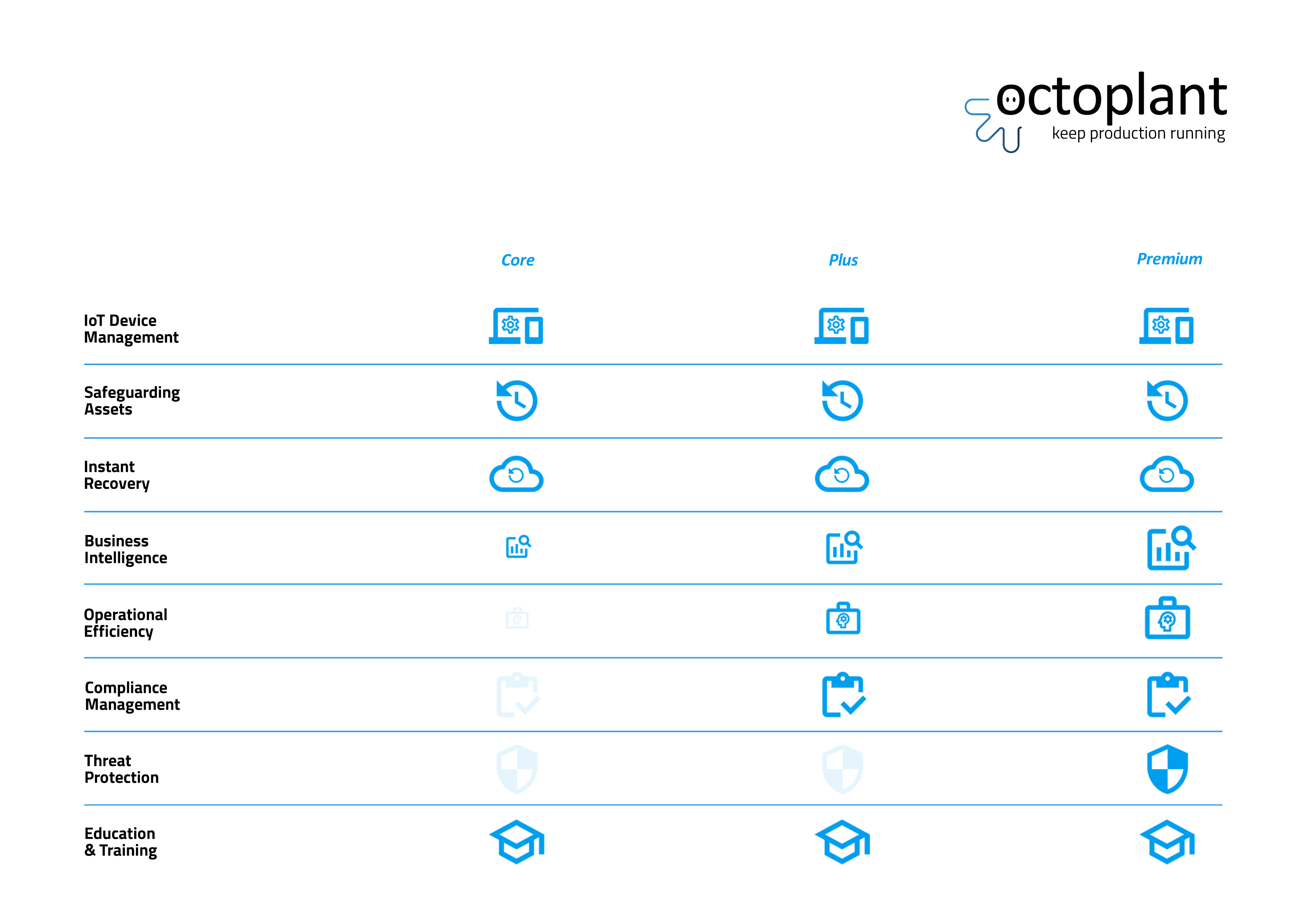

A comparison of the module packages: Core, Plus or Premium?

octoplant solutions are available in three versions – Core, Plus and Premium. This gives companies great flexibility. Decide for yourself which parts of the modular system you want to use in the future. Implement the functions that fit your specific plant.

All Manufacturer Device Support

Use one single software system and one single strategy for all your automation equipment.

Below are many of the devices and engineering platforms that our customers commonly manage with octoplant. NOTE: octoplant device support is NOT LIMITED to those listed.

PLCs

- AEG

- B&R Automation Studio

- BECKHOFF TwinCAT

- BOSCH CPS21

- BOSCH Indralogic

- CODESYS

- EATON

- ELAU

- Emerson Proficy ME (formerly GE)

- HITACHI

- IBHsoftec S5 for Windows

- IBHsoftec S7 for Windows

- MITSUBISHI GX Works2

- Phoenix CONTACT PC WORX

- Pilz

- Rockwell Automation RSLogix 5

- Rockwell Automation RSLogix 500

- Rockwell Automation RSLogix 5000

- Schneider Electric Concept

- Schneider Electric Modsoft

- Schneider EcoStruxure Control Expert (formerly Schneider Unity)

- Schneider PL7 Pro

- Siemens SIMOTION

- Siemens SIMATIC STEP 5

- Siemens SIMATIC STEP 7

- Siemens SIMATIC STEP 7 Multiproject

- Siemens TIA Portal with STEP 7

- WAGO

- …

DCS / SCADA / HMI

- ABB Freelance

- AVEVA InTouch HMI (formerly Wonderware)

- AVEVA Plant SCADA (formerly Citect)

- AVEVA System Platform (formerly Wonderware)

- COPA-DATA zenon

- General Electrics GE Proficy iFix

- Rockwell FactoryTalk View ME/SE

- Siemens PCS7

- Siemens ProTool

- Siemens WinCC

- Siemens WinCC flexible

- …

ROBOTS

- ABB

- COMAU

- FANUC

- Kawasaki

- KUKA

- MITSUBISHI

- OMRON Adept

- Stäubli

- YASKAWA MOTOMAN

- …

CNCs

- FANUC

- Indramat

- Siemens SINUMERIK 840D Operate

- Siemens SINUMERIK 840D HMI Advanced

- …

IT

- Hirschmann Belden switches

- Phoenix mGuard Routers

- Rockwell Allen Bradley Stratix

- Siemens SCALANCE Switches

- PC Images with Drive SnapShot

- PC Images with Acronis

- …

UNIVERSAL

- Adobe PDF

- ASCII

- Binary

- CSV

- FTP

- Microsoft Excel

- Microsoft Word

- Network (UNC)

- SSH

- XML

- …