Engineered Cabinet Solutions

Save time. Save space. Save money

Save time

Standard design and application specific cabinet solutions saves you time in engineering and in project estimation

Save space

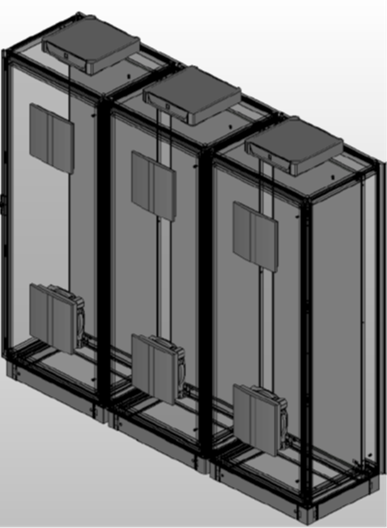

With a broad range of options at our disposal, we can solve common plant room real estate issues with ease

Save money

Innovative engineering and intelligent heat management equals high efficiency and extended product life

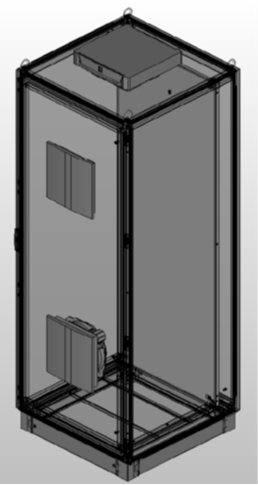

Enclosed drive solutions using standard Rittal enclosure systems.

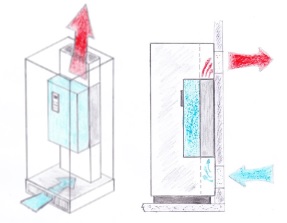

Intelligent heat mitigation

We offer our clients a multitude of options to ensure the heat created by variable speed drives is dealt with in the most efficient of ways. Air flow in and out the rear of a cabinet dramatically reduces the load of the plant room air conditioning or a more typical design with cool air being pulled in the bottom and dispersed into the plant room out the top. Direct channeling of air through the VSD heat sink minimises in cubicle cooling requirements and increases the life of the electronics.

Options

- Top or bottom cable entry

- Local isolators, circuit breakers, fuses, etc.

- Contactor by-pass

- Dynamic braking

- HMI, PLC and automation options

- Fieldbus, closed loop and I/O options

- Local control station

- Reactors, dv/dt or sine wave filter

- Low harmonic drives – passive or active harmonic mitigation

- Active front end

- 415 Volt, 690 Volt or 1000 Volt options

- Designs to 50° C ambient

- Liquid cooled drives

- High power designs to 1200 Amps

Industries

- Water treatment plants

- Sewerage treatment plants

- Water authorties and councils

- River irrigation systems

- Mining

- Power stations

- Metals

- Long haul conveyors

- Ball mills