Production Security Through Innovative Data Management with Octoplant

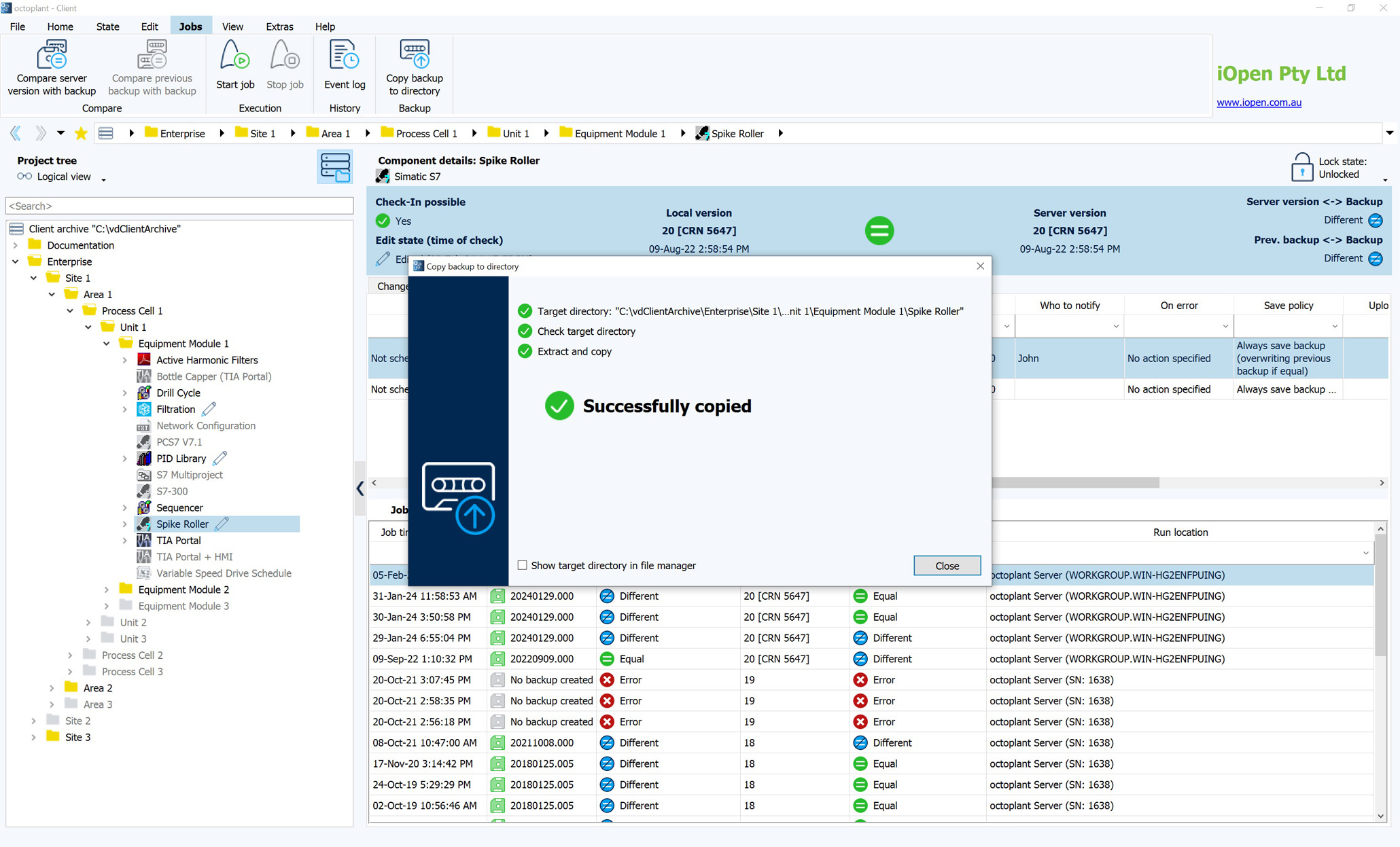

Octoplant presents an agnostic solution that automatically secures configurations and project statuses for a broad range of automation devices. It operates transparently, without dependence on specific vendors and adheres to common industry standards. Octoplant stands out by supporting an extensive array of devices from manufacturers worldwide. Continuous access to the current setup and clear visibility into all changes facilitate the prevention of production downtimes, leading to increased production efficiency.

In our personal lives, backing up apps and photos on mobile phones is a common practice. In the context of large-scale industrial production, this becomes even more crucial, though it is not universally implemented. While individual device backups can be easily performed with a USB stick, the complexity increases in industrial settings with multiple components from various manufacturers. Octoplant addresses this challenge by providing tailor-made versioning and operational technology (OT) backups. It ensures the secure operation of automated production processes by transparently managing changes to production systems, even in heterogeneous environments.

Overview of Complex Processes

Octoplant supports the integration of diverse automation technologies, allowing manufacturers to record changes to OT configurations and project statuses independently of the device manufacturer. This bridges the gap between OT and IT, ensuring robust and controllable automated production in line with high IT standards. Octoplant’s compatibility with automation devices from different manufacturers positions it as a global leader. It can seamlessly integrate with systems from renowned manufacturers like Siemens, Rockwell Automation, Schneider Electric, Emerson, or Omron. This comprehensive coverage enables the protection, security, and versioning of nearly every element in a production system within a single platform – and everyone involved knows what was changed, when and by whom.

Backups for Smooth Processes Worldwide

The platform not only monitors changes and compliance with rules and standards but also enhances security by revealing potential gaps. Octoplant’s reliable backup solution addresses the challenge of handling a large volume of automation devices, as demonstrated by a car manufacturer performing 20,000 backups nightly. The software identifies changes in automation processes, highlights unforeseen deviations, and compiles configurable notifications, ensuring relevant information reaches the right people promptly.

Octoplant’s on-premise, server-based data management operates within your demilitarized zone. Accessibility to individual asset metadata is available from anywhere, making the entire production backup status globally transparent. It plays a crucial role in data management on a global scale, aiding companies in effectively handling their data.

In an Emergency: Disaster Recovery

In case of emergencies, such as the one faced by a US producer of cleaning and hygiene products in February 2023, Octoplant proves invaluable. Following a significant error due to unnoticed changes in the automation program, the company had to recall almost five million defective bottles of a cleaner. Octoplant’s disaster recovery feature allows maintenance teams to reset programs to a previous system configuration in the event of a failure. It not only restores the latest status but also compares change details, helping determine the last error-free system operation. This version can then be swiftly restored and integrated into the production process, ensuring a quick return to smooth operation.

Considering the magnitude of Octoplant’s benefits, it is unsurprising that approximately 60 percent of well-known production companies worldwide rely on it, with 3,000 customers globally putting their trust in Octoplant.

If you’re interested in learning more about Octoplant, please fill out our online contact form and we’ll be in touch as soon as possible.