A Hygienic Solution for the Food and Beverage Industry

Food and Beverage

In the food and beverage industry, maintaining a high level of hygiene is of utmost importance. The setup of production facilities in this sector may seem similar to the industrial world, but the regulatory requirements and guidelines are significantly more onerous. Recognizing these unique challenges, EXOR International has developed the eX700FB series, a specialized range of Human-Machine Interface (HMI) devices tailored to meet the stringent demands of the food and beverage industry.

Adaptation for a Hygienic Solution

EXOR International has taken its highly successful eX700 Series and made specific adaptations to ensure compliance with the CEI EN 60529 guidelines. The company has demonstrated an incredible level of attention to detail in eliminating the accumulation of food, grease, and product powder particles on the device.

Key Features and Benefits

The ex700FB Series offers a range of features that make it an exceptional choice for the food and beverage industry, particularly in dairy and meat processing sectors. Let’s explore some of its standout features:

1. Extensive Guarantee and Protective Casing: Despite its absence of a protective casing, the ex700FB Series provides an extensive guarantee, ensuring long-term usability in demanding environments.

2. Ease of Cleaning: The device is designed for easy cleaning, allowing efficient maintenance, and minimizing downtime in food processing facilities. These HMI’s feature rugged stainless-steel fronts that are highly polished. This design allows particles to easily flow away from the surface, making it easier to maintain cleanliness. Moreover, the frame of the device has been carefully designed to have the optimal angle of contact with the machine surface. This facilitates the effective washing away of cleaning liquids while also preventing the retention of bacteria or microbes.

3. High Protection Front Panel IP69 Rating: With a high protection front panel rating of IP69, the ex700FB Series resists frequent washing with high-pressure, high-temperature water. They can withstand rigorous cleaning procedures while maintaining optimal performance.

4. Stainless Steel Bezel and Acid Chemical Resistance: The perfect stainless steel bezel design enhances durability and ease of cleaning. Additionally, the ex700FB Series is resistant to acid chemicals commonly used in food processing, ensuring longevity in harsh environments.

5. Food Compliant Gasket: Equipped with a food-compliant gasket, the device meets regulatory requirements and maintains hygienic standards. These HMI’s meet the guidelines specified by DIN EN1672-2, ensuring their suitability for use in food handling and processing. Additionally, they adhere to standards set by EHEDG (European Hygienic Engineering and Design Group) and FDA (Food and Drug Administration) 21 CFR 177.2006, further validating compliance with hygiene requirements.

6. Projected Capacitive (PCAP) Touch Technology: The ex700FB Series features Projected Capacitive (PCAP) Multi Touch technology with numerous advantages over Resistive Touch technology in applications where customers require a more rugged surface due to susceptibility to scratches. Furthermore, the improved algorithm on these PCAP HMI’s enables the touchscreen to be operated by workers wearing working or safety gloves.

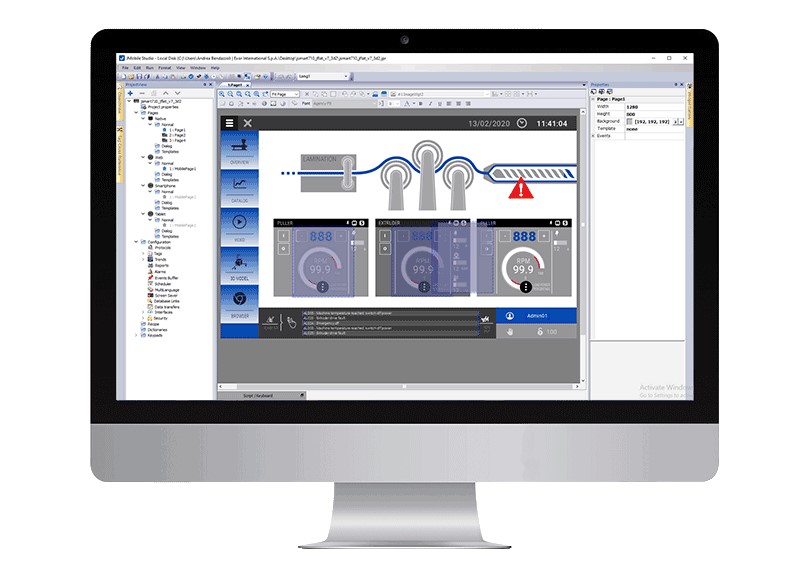

Programming Software

JMobile Visualisation: The ex700FB Series of HMI’s runs on the JMobile software, a powerful and intuitive visualization software developed by EXOR International. JMobile allows engineers to create user-friendly applications without requiring expertise in programming languages like HTML5, CSS, or Javascript.

The JMobile software is specifically designed to complement the hardware and firmware of the ex700FB Series, ensuring optimal performance in robust and long-lasting industrial environments. It covers various essential aspects of IIoT platform architecture, including connectivity, device management, process management, and data visualization.

Codesys PLC: Connectivity is facilitated through a fully integrated CODESYS PLC, enabling communication with I/O devices, sensors, and motion devices using protocols such as PROFINET, EtherCAT, POWERLINK, EtherNet/IP, Modbus, and many others. Data transmission is carried out using the secure and robust OPC UA standard, allowing seamless sharing of data within the network of edge points as well as transmitting data to higher enterprise levels and external interfaces.

Extensive Libraries: Beyond its impressive communication capabilities, JMobile offers a complete package for visualization. It provides an extensive library of stunning graphic elements that can be easily implemented, resulting in clear and visually appealing visualizations.

HTML5 Web Technologies: As the market trends towards more complex web applications, JMobile is prepared to adapt. Its client-server architecture is compatible with current HTML5 web technologies and utilizes a QT engine and Scalable Vector Graphics (JM4Web). This enables advanced control and remote supervision from any browser and any device, including smartphones, tablets, and computers.

Overall, JMobile enhances the capabilities of the ex700FB Series by providing a powerful and versatile software solution. It simplifies application development, ensures reliable connectivity, and offers advanced visualization and control options for industrial environments.

Reliability and Excellence

The ex700FB Series from EXOR International is a reliable HMI that offers a hygienic solution tailored specifically for the food and beverage industry. Its compliance with strict guidelines, rugged construction, and compatibility with the JMobile software make it an ideal choice for applications in dairy and meat processing sectors. By choosing the ex700FB Series, companies can ensure compliance with hygiene regulations, enhance operational efficiency, and maintain the highest standards of cleanliness and safety in their facilities. iOpen, as a supplier of automation and communication solutions, can provide access to this innovative product from EXOR International, empowering businesses in the food and beverage industry to achieve excellence in their operations.

If you’re interested in learning more about the ex700FB Series, please fill out our online contact form and we’ll be in touch as soon as possible.